Our Strengths

Teknoflow Infrastructure

Mild Steel Work Shop

AREA

Under shed: 50000 SQFT

Open : 35000 SQFT

CRANES

25 Tons : 1 No.

15 Tons : 1 No.

10 Tons : 1 No.

5 Tons : 5 Nos.

3 Tons : 4 Nos.

Stainless Steel Shop

AREA

Under shed : 25000 SQFT

CRANES

10 Tons : 1 No.

5 Tons : 1 No.

Teknoflow Machinery

German make

Radial Drill Machine

Conventional Lathe machine having

machining OD up to 1800mm

Small Radial Drilling machine

with high accuracy

Forming Equipment

Sheet shearing machine

3100 mm x 10 mm thick

CNC profile cutting machine with plasma source and oxy gas cutting heads

2500 mm x 12000 mm x 30 mm thick

Plate bending roller

2500 mm x 45 mm thick

Welding Competency

WPS and PQR Qualified by Lloyds, TUV, BV

SAW Machine:With Column and Boom, Portable

Automatic L seam & C seam welding: TIG Welding, CO2 Welding

Materials

- Carbon Steel

- Corten Steel SA 242

- Stainless Steel 304 / 316 L

- Stainless Steel 904

- Stainless Steel 310 / 321

- Duplex 2205

- Cupronickel

- LTCS & HTCS – SA387 GR22

Surface Preparation

Shot Blasting Section

Size: 7m X 7m X 16m

Pollution Control Board Approved with dust collector, PPE and human safety

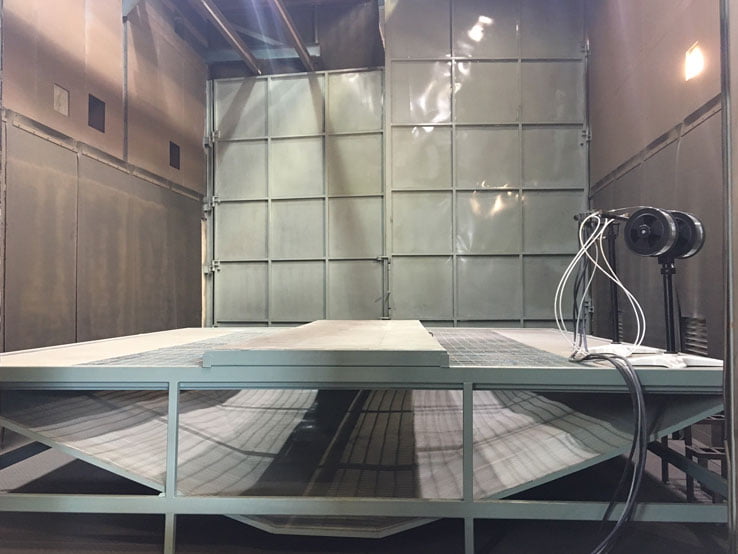

Painting Section

Size: 7m x 7m x 12m

Air Pressure Spraying, Airless Spraying

Humidity and Temperature Controlled

Metalizing Section

Size : 7m X 7m X 4m

Aluminum Metal spraying

up to 300 microns

Other Facilities

Buffing, Pickling & Passivation, Powder Coating,

Blasting and Painting on conveyor

Inspection Competency

- Hydro Testing – pressure upto 500 bar

- Pneumatic Test – pressure upto 30 bar

- Magnetic Particle Test Kit

- Liquid Penetration Test Kit

- Blast Surface Profile Kit

- Weld Gauges

- Gloss Meter

- Paint DFT Meter

- Vernier Caliper 2500 mm

- Laser Thermometer, Hygrometer

- Bend Tester-180° (Mandrill dia-12.5 mm)

- Al.Metalizing Pull off Adhesion Hydraulic Tester. (350 bar)

- Height Gauge (600 mm)

- Surface Plate (900 x 600 mm)

Handling Equipment

Cranes Capacity

- 25 metric ton – 25 m span x 8 m lift

- 15 metric ton – 25 m span x 8 m lift

- 10 metric ton – 25 m span x 8 m lift

- 5 metric ton – 25 m span x 8 m lift

- 3 metric ton – 12 m span x 4 m lift – 2 nos

Teknoflow Design / Engineering Competency

Design Competency

(In-house)

Mechanical Design

Detailing and Drafting

(Collaboration / Outsourced)

Thermal Design

Process Design

Software (In-house)

- HTRI

- PV Elite

- Solid Works

- AutoCAD

Software (Out Sourced)

- NozzlePro

- Staad Pro

- Ansys

- Tekla

Our Strengths

- Helped customer export different products to over 25 countries

- Ability to deliver products to end customer in various countries

- Customer Satisfaction – 97 %

- Quality Performance – 98 %

- Delivery Performance – 99 %

Export Capabilities

- Documentation in various languages

- Export – Import License

- Logistic support to various countries

- Statutory compliances for export

Procedures We Follow

- Kaizen Technique – Small Continual Improvements

- 5 S Technique

- Use of Poka-Yoke – Lean Manufacturing

- ProcessMapping – Identify, Reduce or Eliminate NVA’s

- Root Cause Analysis

- Training and Qualification for Critical Processes

- Visuals to Monitor and Review the Results

- Initiatives to Improve Work Environment and Safety (EHS)

Ensuring Product Quality

- Controlling quality of inputs

- Monitoring supplier quality and delivery performances

- Monitoring quality during production by checking

- In process Rework

- In process Rejection

- Internal Quality Assurance Plan

- Process Flow Diagrams at Shop floors

- Standard Operating Procedures

WELDING COMPETENCIES

- Welding Process Qualified as per ASME Section IX – GMAW, GTAW, SMAW

- Welding Process Qualified as per PED – GTAW, SMAW

- Welding Inspector as per ASME, EM Section IX

- Visual Testing

- Liquid Penetration Testing

- Magnetic Particle Testing

MATERIALS COMPETENCIES

- Carbon Steel

- Corten Steel SA 242

- Stainless Steel 304 / 316 L

- Stainless Steel 904

- Stainless Steel 310 / 321

- Duplex 2205

- Cupronickel

- LTCS & HTCS – SA387 GR22

PAINTING COMPETENCIES

- Painters Qualified as per ASTM – D 4228-05 (2012)

- Separate Paint Booths

- Air Pressure and Airless Spray Painting Equipment

- Painting Inspection Gauges

BLASTING COMPETENCIES

- Surface Preparation as per SA 2 1/2

- Separate Blasting Booth

- Blasting Inspection Gauges

Quality Policy

We, at Teknoflow Green Equipment Pvt. Ltd, are committed to Manufacturing & Supply of Pressure Vessels, Exhaust Systems Pipings, Heavy Structures and Equipments for Water Treatment to achieve “Delightment” of all Stakeholders. We shall achieve this by:

- Marching towards Zero defects in every activity of the organization

- Providing products and services which exceed customer expectations

- Training to our employees for continual improvement

Teknoflow Green Equipments Private Limited

S. No. 19/2, Ambe Bahula,

Nashik 422010, Maharashtra, India.

Pune Office:

Baner Business Bay,

3rd Floor, S. No. 52, Baner-Sus Road,

Baner, Pune, Maharashtra - 411045.

Stay In Touch

Contact Details

General :

+91-253-2336005 | info@teknoflow.coMarketing & Sales :

+91 77220 95996 | info@teknoflow.coProcurement :

+91 77220 95418 | yogesh.kadam@teknoflow.co +91 77220 21131 | mahesh.bhalke@teknoflow.co